Exactly How OEM Building And Construction Parts Can Improve the Effectiveness and Durability of Your Machinery

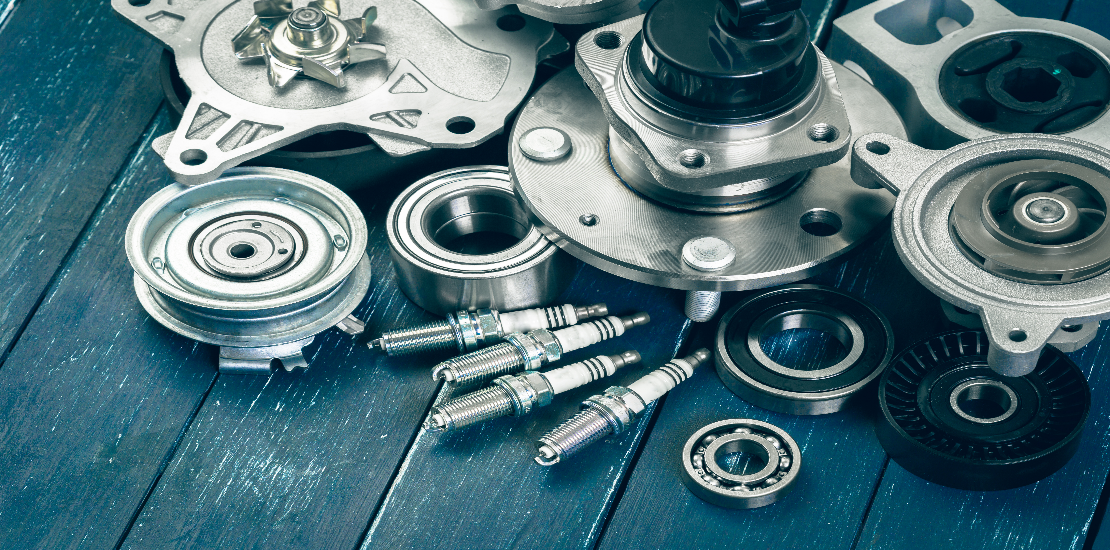

When it comes to preserving the peak efficiency of your machinery, the selection of components plays a critical duty in making certain efficiency and durability. OEM construction parts, crafted especially for your equipment by the initial supplier, supply a level of accuracy and compatibility that can dramatically affect your procedures. The use of these parts surpasses mere substitute, influencing the general performance and sturdiness of your equipment. Let's discover how selecting OEM construction parts can be a game-changer in maximizing your equipment's possible and minimizing operational interruptions.

Relevance of Making Use Of OEM Components

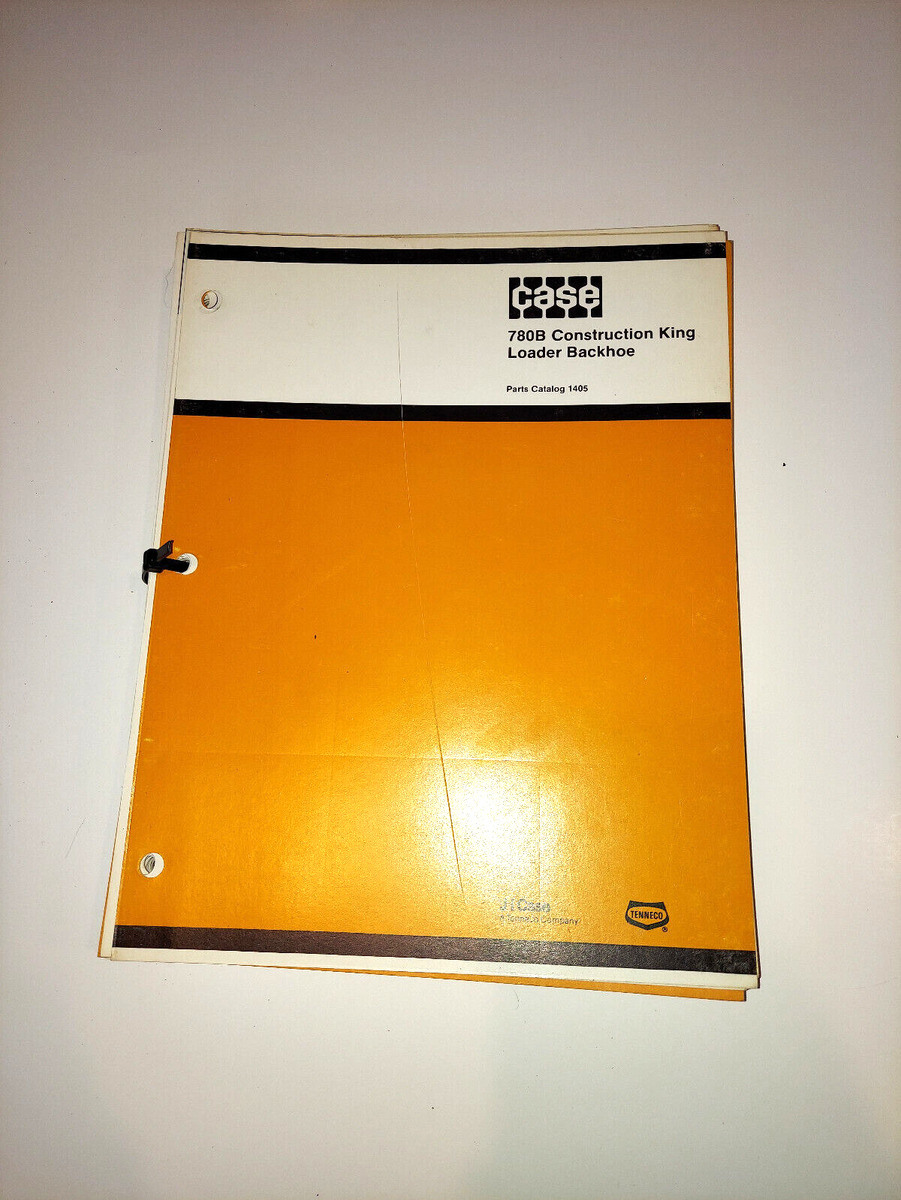

Utilizing initial tools manufacturer (OEM) components is paramount in making sure the ideal efficiency and longevity of equipment (Oem Construction Parts). OEM components are specifically designed to fit the machinery they are planned for, making sure seamless combination and compatibility. These components undertake strenuous screening to meet the supplier's standards, guaranteeing reliability and toughness

One of the essential advantages of using OEM components is their quality control. Manufacturers generate OEM components to specific specs, preserving the high requirements needed for effective equipment procedure. This quality guarantee equates to improved efficiency, decreased downtime, and reduced maintenance expenses in the future.

Moreover, OEM components frequently come with service warranties, giving customers with added comfort. In the occasion of any kind of problems, OEM components are backed by the producer, making certain assistance and help when needed. Selecting OEM components over aftermarket alternatives can ultimately conserve time and cash while taking full advantage of the efficiency and durability of machinery.

Improved Tools Efficiency

Offered the vital relevance of using OEM parts for machinery to ensure optimal performance and durability, the emphasis now changes to how these real elements add to boosted devices performance. OEM components are particularly created and made to satisfy the precise specifications of the machinery they are intended for, making sure a best fit and seamless combination. This precision in design and compatibility converts directly into enhanced devices efficiency.

Additionally, OEM components commonly undertake extensive testing and quality assurance procedures to fulfill market criteria and producer needs. This adherence to quality control additionally reinforces devices performance by making sure reliability, toughness, and consistency in operation. By choosing OEM components, equipment operators can considerably improve the performance and efficiency of their devices, eventually leading to boosted productivity and long life.

Extended Machinery Lifespan

With try these out a focus on long term sturdiness and operational efficiency, prolonging the lifespan of machinery stays a crucial objective in the realm of equipment maintenance and management. By purchasing OEM building and construction parts, equipment drivers can significantly add to the long life of their equipment. OEM components are specifically developed to fit the specific requirements of the initial equipment, making certain seamless combination and optimum efficiency.

Extensive equipment life-span not only minimizes the frequency of expensive substitutes yet likewise boosts the overall productivity of a building operation. By using authentic OEM parts, operators can mitigate the danger of unexpected breakdowns and downtime, ultimately resulting in raised efficiency and profitability. Furthermore, OEM components typically feature guarantees, giving additional guarantee of their top quality and integrity.

Routine upkeep regimens that consist of using OEM components can help avoid premature deterioration, guaranteeing that equipment operates at its peak efficiency for a prolonged duration. Focusing on the usage of OEM construction components is vital to making the most of the lifespan of equipment and safeguarding long-term functional success.

Lowered Downtime and Maintenance Expenses

By making use of OEM building components specifically developed for your equipment, you can considerably minimize downtime created by unforeseen break downs. OEM parts are crafted to fit and work perfectly within your devices, minimizing the threat of breakdowns that can lead to costly downtime.

Reduced downtime directly associates to reduce maintenance costs. The demand for constant repair work and component substitutes reduces when machinery runs effectively with the usage of OEM components. This not just saves cash on purchasing aftermarket parts however additionally lowers labor expenses connected with frequent maintenance. Purchasing high-quality OEM building and construction parts can lead to a more cost-effective maintenance approach in the future, ensuring that your equipment stays productive and functional for extended durations without sustaining substantial maintenance expenses - Oem Construction site Parts.

Guarantee and Top Quality Guarantee

In addition, the guarantee on OEM parts typically extends past just the replacement of the component itself, encompassing any kind of damages or issues that might develop because of the faulty component. This extensive coverage not just protects the first investment in the equipment however also safeguards versus unexpected fixing expenses.

Verdict

In conclusion, using OEM building and construction components can dramatically improve machinery efficiency and durability. Generally, OEM components play an essential function in maximizing the efficiency and resilience of building equipment.

Using initial tools supplier (OEM) components is paramount in ensuring the ideal efficiency and long life of equipment.Given the paramount importance of utilizing OEM components for equipment to make sure ideal efficiency and durability, the focus now changes to exactly how these real parts contribute to improved equipment performance. By choosing OEM parts, equipment operators can substantially improve the performance and efficiency of their equipment, ultimately leading to raised performance and durability.

By investing in OEM building parts, equipment operators can dramatically add to the durability of their machinery. When equipment runs effectively with the use of OEM components, my sources the need for frequent repairs and component replacements decreases.